ABB Robotics’ third Automotive Manufacturing Outlook Survey, in partnership with the leading publication Automotive Manufacturing Solutions, has highlighted how moving to the “Smart Factory” is viewed as a critical next step by global manufacturers and major suppliers.

“Automotive manufacturers are acutely aware that advanced robotics, Artificial Intelligence and digital twinning technology are positive drivers of change,” said Joerg Reger, Managing Director of ABB Robotics Automotive Business Line. “Together, these technologies are forming the building blocks of ‘Smart Factories’ which will help carmakers introduce new models more quickly and cost-effectively, while greatly reducing energy consumption and costs and meeting sustainability targets.”

The benefits of increasing the use of advanced manufacturing technologies, ranging from AI-powered autonomous mobile robots which deliver parts to the line to digital twinning technology, all featured prominently in the latest Manufacturing Outlook Survey.

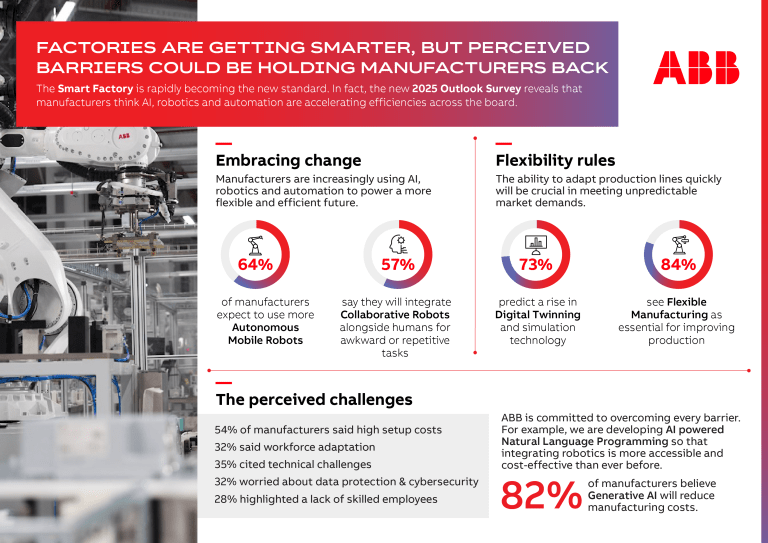

The survey again highlighted the importance of robotics and advanced automation with 64 percent of respondents agreeing there would be an increase in the use of autonomous mobile robots (AMRs) in automotive manufacturing, while 57 percent agreed that more collaborative robots (cobots) will be introduced alongside workers to perform repetitive assembly tasks.

Respondents cited a major leap for the industry driven by generative AI and software, with 82 percent agreeing that leveraging this technology had the potential to reduce vehicle manufacturing costs, improve quality and streamline the introduction of new models. The adoption of another key technology, digital twinning and simulation, was also expected to rise significantly with 73 percent predicting greater uptake.

The survey also underlined how the uptake of flexible manufacturing was viewed as a crucial way to navigate the complexities many well-known manufacturers face. These include unpredictable levels of demand for certain vehicle types including EVs, hybrids and ICE vehicles, with manufacturers needing to assemble different powertrains on a single site, while maintaining faster product lifecycles. Over the next five years, 84 percent of those surveyed said flexible manufacturing would be a significant factor in vehicle manufacturing.

“Flexible manufacturing is essential when it comes to managing the very real complexities, as well as financial commitments, many carmakers currently need to tackle, and is an approach ABB Robotics has pioneered for our customers,” adds Reger.

“The ability to quickly add extra and different assembly capacity as a module – when customer demand for a particular model suddenly increases or a new powertrain is available – without disrupting production or requiring significant capital expenditure remains vitally important.”

While survey respondents supported the introduction of new technology and viewed the future smart factory positively, there was recognition of some of the challenges involved in reaching this destination. High initial costs (54 percent) were viewed as the biggest constraint while technical challenges (35 percent), cybersecurity and data protection (32 percent) all featured prominently as did workforce adaptation (32 percent) and the lack of skilled employees (28 percent).

“The industry is positive about change and understands in detail which technologies offer the best solutions with autonomous mobile robots, cobots and AI featuring very prominently,” said Daniel Harrison, chief analyst for Automotive Manufacturing Solutions.

“But as we move to automotive smart factories the human factor can’t be ignored, concerns over workforce adaption and a perceived lack of employees skilled in IT were again highlighted by respondents. The industry’s technology partners need to play a major role in training and education as well as unlocking ways to introduce key advances like AI technology in a non-disruptive and accessible way.”

ABB Robotics continues to support the integration of AI with robotics with a particular emphasis on developing natural language programming. In 2024, the company’s AI Start-Up Challenge named T-Robotics and Mbodi as winners. T-Robotics enables natural conversation while maintaining precision; Mbodi’s platform allows robots to learn and adapt to new tasks through spoken language.

Advancements are also being made in autonomous planning capabilities, with VSLAM (visual simultaneous localization and mapping) ABB AMRs equipped with environmental awareness, real-time decision making and semantic differentiation between people and objects. This means they can navigate autonomously in automotive manufacturing environments while performing tasks like tracking stock inventory as they go, sharing this information with other robots, and collaborating safely side-by-side with humans.